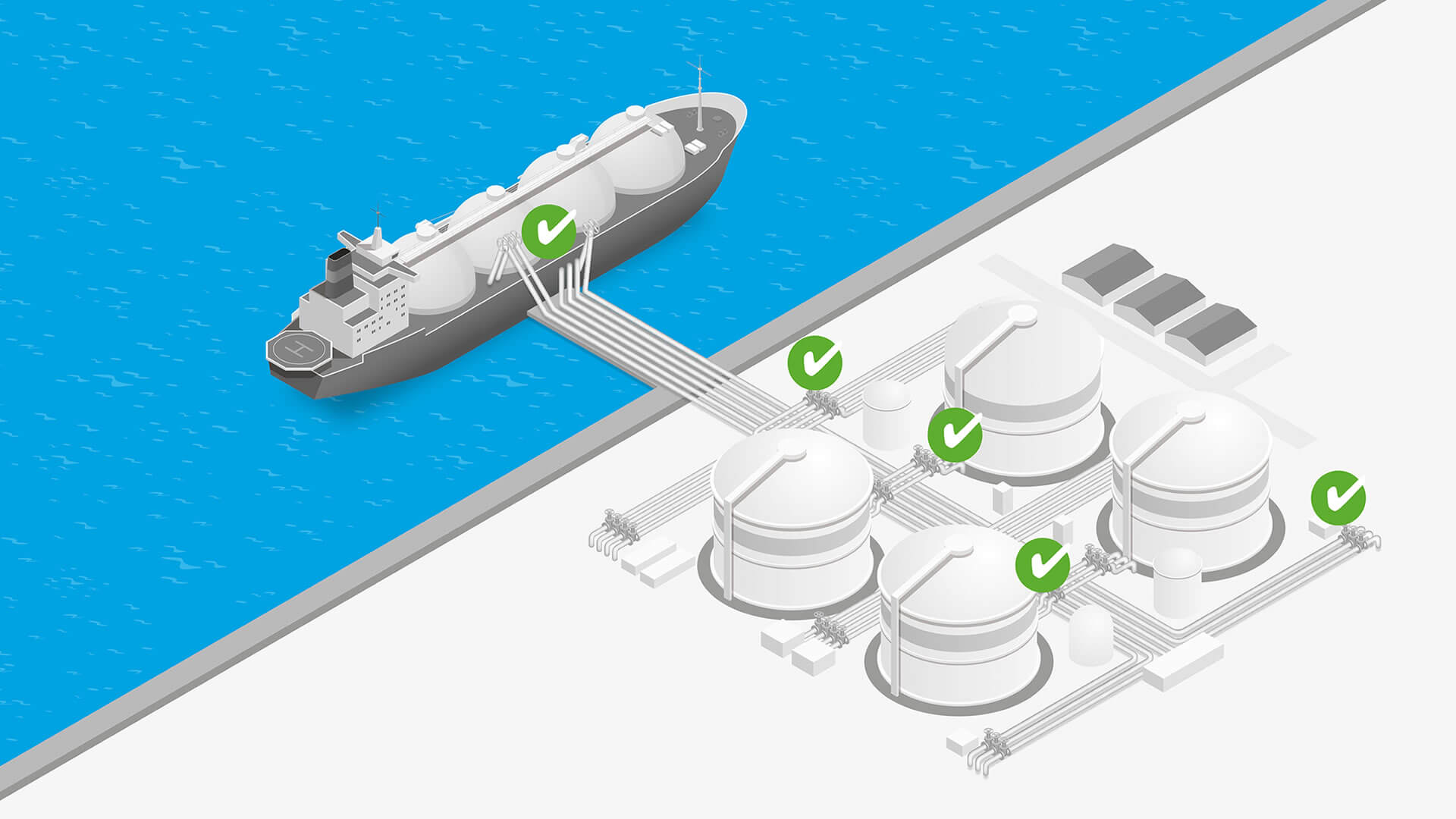

Rule out loading errors and unwanted product mix by guaranteeing a correct valve line-up.

Valve line-up system

3 steps to zero contamination

Step 1

DCS determines which valves are to be operated.

Step 2

Only the nominated valves can be operated.

Step 3

Product transfer will only occur with correct line-up.

Guaranteed right-first-time operation

With valve interlocks you guarantee that no valve is operated accidentally. They are only unlocked by uniquely coded keys. These keys are only released by the Key Management System upon authorisation by your Control System.

More reliable than full actuation

Our valve-line up system offers better security than complete valve actuation. Through their mechanical key principle, valve interlocks cannot be bypassed. Actuators can be operated in the field through their local controls, outside the control of the control room, bypassing their automated settings.

Limited investment

Compared to full automation, valve line-up systems are very cost effective. They involve relatively low hardware costs, require limited wiring and automation and need considerably less periodic maintenance.

Case study

In the tank storage industry, product contamination during product movements is a common issue. A leading tank storage company managed to avoid product contamination during cargo loading with a dedicated valve-line up system.