Designing robust safety systems for cracking furnace processes

Guaranteeing safe cracking furnace processes

For any plant manager or operations manager – who is busy balancing productivity, operational downtime, safety, and budgets – steam cracking furnace operations need a robust, methodical and trustworthy system to monitor and control standard and non-standard operations.

Steam cracking is potentially dangerous and complex to manage

Steam cracking is a petrochemical process in which saturated hydrocarbons are broken down into smaller, often unsaturated, hydrocarbons. It is the principal industrial method for producing the lighter alkenes (or commonly olefins), including ethene (or ethylene) and propene (or propylene). Steam cracking furnace operations are generally known to be potentially dangerous and complex to manage. There have been, over the years, serious accidents and incidents involving steam cracking operations that illustrate the dangers involved.

Understanding the issues around steam cracking

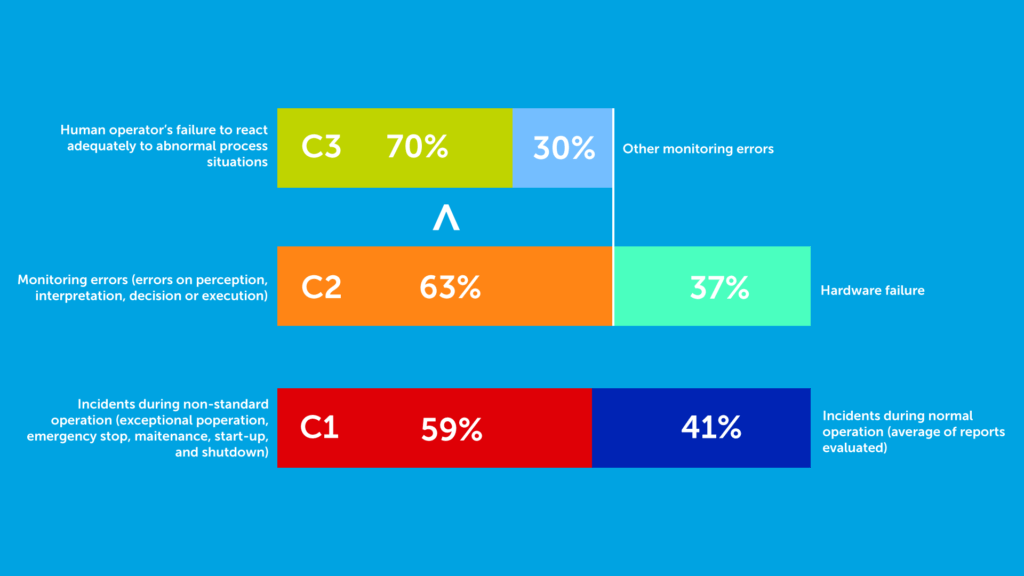

Data from recent incident and accident investigations identifies that the major direct causes of processing function-related accidents are found in non-standard operations and monitoring errors; the operator’s overly delayed reaction to a nonstandard situation, perception error, and interpretation error. Reported numbers of incidents during non-standard operations range from 53% to 72% of all incidents and accidents. These may mean circumstances such as emergency stop, maintenance, furnace switchover, and start-up or shutdown operation.

When and where do incidents occur?

The areas where incidents or accidents have a high probability of occurring are start-up, shutdown and hot-swapping processes.

Important causes for incidents traditionally not coverable by process control automation include:

- Non-standard operations, for the biggest part involving manual process operator interference

- Errors in monitoring the process

- Failures to react adequately to non-standard situations

Typically, operating procedures are intended to avoid a wide variety of incidents and accidents including:

- Release of hydrocarbons into the atmosphere

- Release of oxygen towards the backend, downstream of the cracking process

- Hydrocarbons that come into contact with oxygen

- Spectacle blinds being turned before the upstream valve closing

- Wrong lineup and sequencing of the upstream and downstream furnace lines

- Furnace mix-up in the swapping process

- Switching to the wrong furnace as compared to the operational plan

- Leading wrong feed(s) or steam (process or utility) to the wrong furnace

Differing furnaces may need different switchover operations

Another complicating and risk-increasing factor in typical (historically stepwise upgraded and expanded) plant situations is that the steam cracking process is at the heart of any refinery and/or petrochemical operations. As such, with furnaces operating continuously, we find that there can be several different generations of furnaces on-site. These differing furnaces may need different switchover operations and control behavior, to do it safely, effectively, and efficiently. With plants carrying several different systems, equipment of different ages, and staff with differing levels of abilities and training, there is always a threat of failure in procedures.

The problems with hot swapping furnaces

Hot-swapping is the transition of a cracking situation of the furnace lined-up to a decoking situation. The decoking should be performed before shutdown and the procedure of hot-swapping a furnace from cracking to decoking and bringing online a new furnace in a hot situation is a high-risk one. Coke formation in the coils reduces the cross-sectional area, increases thermal insulation by which the thermal efficiency of the furnace is decreased, and accelerates the carburization attack of the tube material. For these reasons, typically every 30 to 80 days the furnace needs to run a decoking process to restore furnace operation efficiency. During this process, the furnace is isolated and a flow of steam or steam and air is fed through the coils, transferring carbon into CO and CO2. The parameters in this situation are complex and stochastic and success is highly dependent on a combination of automatically controlled and operator-induced activities. The risk is increased by the fact that the swap must be done within a short time frame. The wrong line-up or combination of feeding, steam, and quench oil sources towards the furnace is another potential source of process failures.

Applying valve interlock systems to cracking furnace safety

Companies who want to successfully and safely manage their steam cracking operation will benefit from Sofis’ integrated approach when installing our products. Sofis’ global team of engineers create customized solutions that take into account differing generations of equipment, current processes and levels of staff training. By integrating our products with your pre-existing systems, seamlessly, we aim to future-proof your plant for many years to come, extending and enhancing your operation.