Chemical plants manufacture or process chemicals using specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries, natural gas processing, and biochemical plants, use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems.

In your facility, you can experience process failures, which can result in contamination, unplanned downtime, loss of production, and potentially hazardous situations leading to accidents and injuries. As a ‘high-risk’ enterprise, you must also comply with strict safety rules. Ensuring safe, efficient, and sustainable valve operation across your facility is key to protecting people, assets, the environment, and profit.

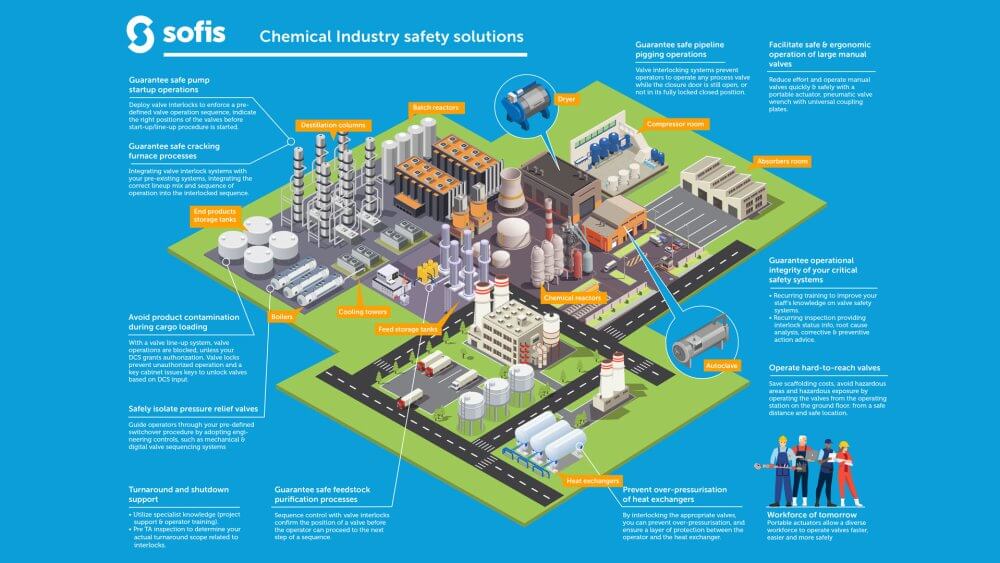

Sofis products and solutions are used in many applications in the chemical industry, to guarantee safe valve operations and improve efficiency.

Guarantee safe pump startup operations

Deploy valve interlocks to enforce a predefined valve operation sequence, and indicate the right positions of the valves before the start-up/line-up procedure is started.

Guarantee safe cracking furnace processes

Integrating valve interlock systems with your pre-existing systems, integrating the correct lineup mix and sequence of operation into the interlocked sequence.

Avoid product contamination during cargo loading

With a valve line-up system, valve operations are blocked, unless your DCS grants authorization. Valve locks prevent unauthorized operation and a key cabinet issues keys to unlock valves based on DCS input.

Safely isolate pressure relief valves

Guide operators through your pre-defined switchover procedure by adopting engineering controls, such as mechanical and digital valve sequencing systems.

Turnaround and shutdown support

- Utilize specialist knowledge (project support and operator training).

- Pre-TA inspection to determine your actual turnaround scope related to interlocks.

Guarantee safe feedstock purification processes

Sequence control with valve interlocks confirms the position of a valve before the operator can proceed to the next step of a sequence.

Guarantee safe pipeline pigging operations

Valve interlocking systems prevent operators from operating any process valve while the closure door is still open, or not in its fully locked closed position.

Facilitate safe & ergonomic operation of large manual valves

Reduce effort and operate manual valves quickly & safely with a portable actuator, and pneumatic valve wrench with universal coupling plates.

Guarantee operational integrity of your critical safety systems

- Recurring training to improve your sta ’s knowledge of valve safety systems.

- Recurring inspection providing interlock status info, root cause analysis, and corrective and preventive action advice.

Operate hard-to-reach valves

Save scaffolding costs, and avoid hazardous areas and hazardous exposure by operating the valves from the operating station on the ground floor, from a safe distance and safe location.

Prevent over-pressurisation of heat exchangers

By interlocking the appropriate valves, you can prevent over-pressurisation, and ensure a layer of protection between the operator and the heat exchanger.

Workforce of tomorrow

Portable actuators allow a diverse workforce to operate valves faster, easier, and more safely.

Download the ‘Sofis solutions for the chemical industry‘ brochure