Sofis recently partnered with a leading customer in the Botlek area of Rotterdam, The Netherlands, to tackle a critical safety challenge at their liquid hydrogen loading stations. The objective was to reduce risks during hydrogen trailer loading operations in ATEX Zone 1, where safety and precision are essential.

Addressing potential human error

In the station’s high-risk ATEX Zone 1 area, operators manually connect hoses to hydrogen trailers and verify the absence of leaks using a pressure transmitter. This verification requires communication with the control room to confirm the correct pressure levels before the valve is opened for loading. The multi-step manual process introduced the potential for human error, raising concerns about operational safety.

Evaluating conventional solutions

The customer initially considered installing valve actuators as a potential solution. However, the high costs associated with installing actuators in ATEX zones and the requirement for local valve operation made this approach impractical.

A tailored safety solution

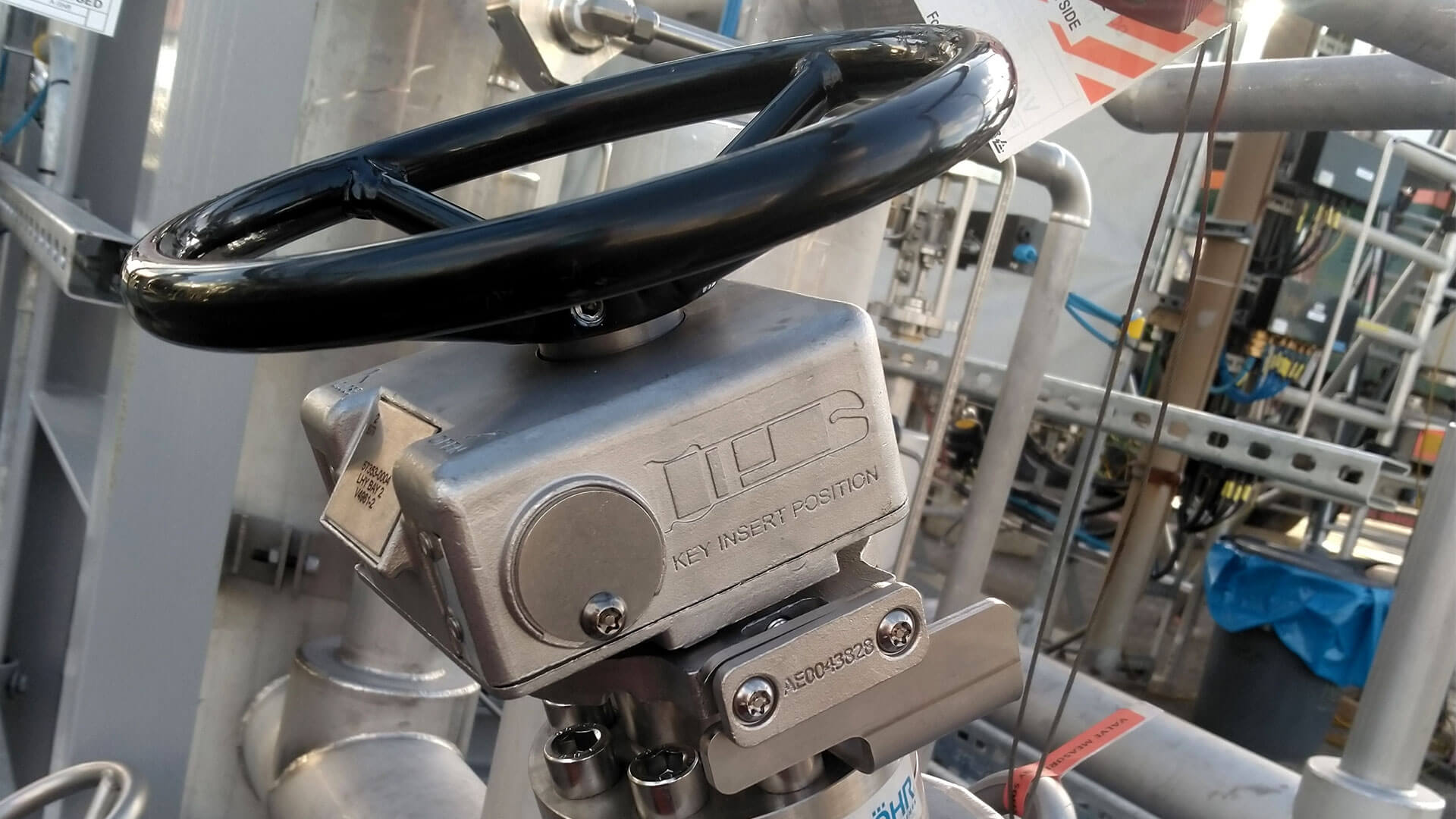

Given their long-standing use of Sofis valve interlocks and confidence in their effectiveness, the customer sought Sofis’ expertise to develop a customized solution. After a detailed assessment of the operational and safety requirements, Sofis implemented an innovative system comprising an Electrical Process Controller Unit (EPCU), installed within the ATEX zone near the valve, incorporating safety parameters from the pressure transmitter.

An integrated valve interlock system, directly attached to the valve, ensures safe operation. The valve can only be opened with the key released by the EPCU. The combined system ensures that valve interlock keys are only released by the EPCU when the correct pressure conditions are met, preventing premature valve operation and effectively mitigating the risk of human error. The solution enhances operational safety and ensures compliance while streamlining the hydrogen loading process.

Proven performance

In operation for over a year, the advanced valve interlocking solution has delivered consistent safety and operational improvements, demonstrating the value of innovative safety solutions in complex industrial environments.