How can you reduce and eliminate the consequences of human error, to increase efficiency and productivity and improve user acceptance of new facilities?

Improving human performance in valve operations

The HSE Accident Prevention Advisory Unit and other institutions have shown that human error is a major contributor in 90% of accidents. 70% of these accidents could have been prevented by management action*. An incident often involves the failure of additional barriers and controls, which may include poor organizational decisions. The aim of Human Factors Engineering (HFE) is to reduce the risk of health to personnel and the environment, to eliminate or reduce the consequences of human error, to increase efficiency and productivity and improve user acceptance of new facilities.

* ‘Human Factors Engineering in Projects’, International Association of Oil and Gas Producers, 2011

Valve analysis

For new plants and facilities, general HFE principles suggest that a valve analysis should be performed, to rank valves based on their importance and frequency of use. Valves should be selected, located, and labelled, so that they can be operated, maintained, and inspected without exposing operators to risk of injury. Equally, accessibility of valves and operational risk should be evaluated in existing plants, so that possible ongoing safety issues are being addressed. HFE design requirements are mainly applicable to manual valves, but also apply to motorized actuators or remotely operated valves, if they may need rapid or frequent manual intervention to override or manually operate them, or to visually check their status.

What task is required?

Human Factors Engineering considerations should include the task involved. What are the operators expected to do? Can they access the valve with ease, or is it located out of reach, or squeezed between other equipment that could prove risky to reach and operate? Does opening and closing the valve require high levels of torque and does it need extreme force? Does it involve repetitive motions with a static or awkward position? Are all members of the workforce capable of undertaking this task? And do environmental conditions play a role in how easily the valve can be opened and closed?

Portable valve actuators support Human Factors Engineering and plant operations

At a petrochemical plant in Singapore, operators were straining themselves to open and close large valves that were not actuated. These valves were gear operated gate valves, requiring two operators to manually open the valve. This took 20 minutes on average. HFE considerations here involved personnel safety and efficiency. The valve operation was physically demanding, labour intensive and took a long time to complete. To support plant operations, a local Sofis partner supplied Sofis EasiDrive portable actuators. EasiDrive is ideal for valves that require a high number of turns or are difficult to operate because of high torque or in situations where climatic conditions can seriously impair operator effectiveness. One operator can open and close multiple valves with a single tool while reducing fatigue and injury risk. It complements the needs of an increasingly diverse workforce and can be used regardless of operator strength. EasiDrive greatly improved productivity and performance at the petrochemical site. It provided operators with complete control, ensuring the required torque was always applied and operators were kept safe, even when under pressure to respond quickly. Only one operator was needed to operate the large gate valves, and the operating time was reduced from 20 minutes to 5 minutes. The risk of injury was alleviated, and it satisfied the general aims of HFE identified by the International Association of Oil & Gas Producers.

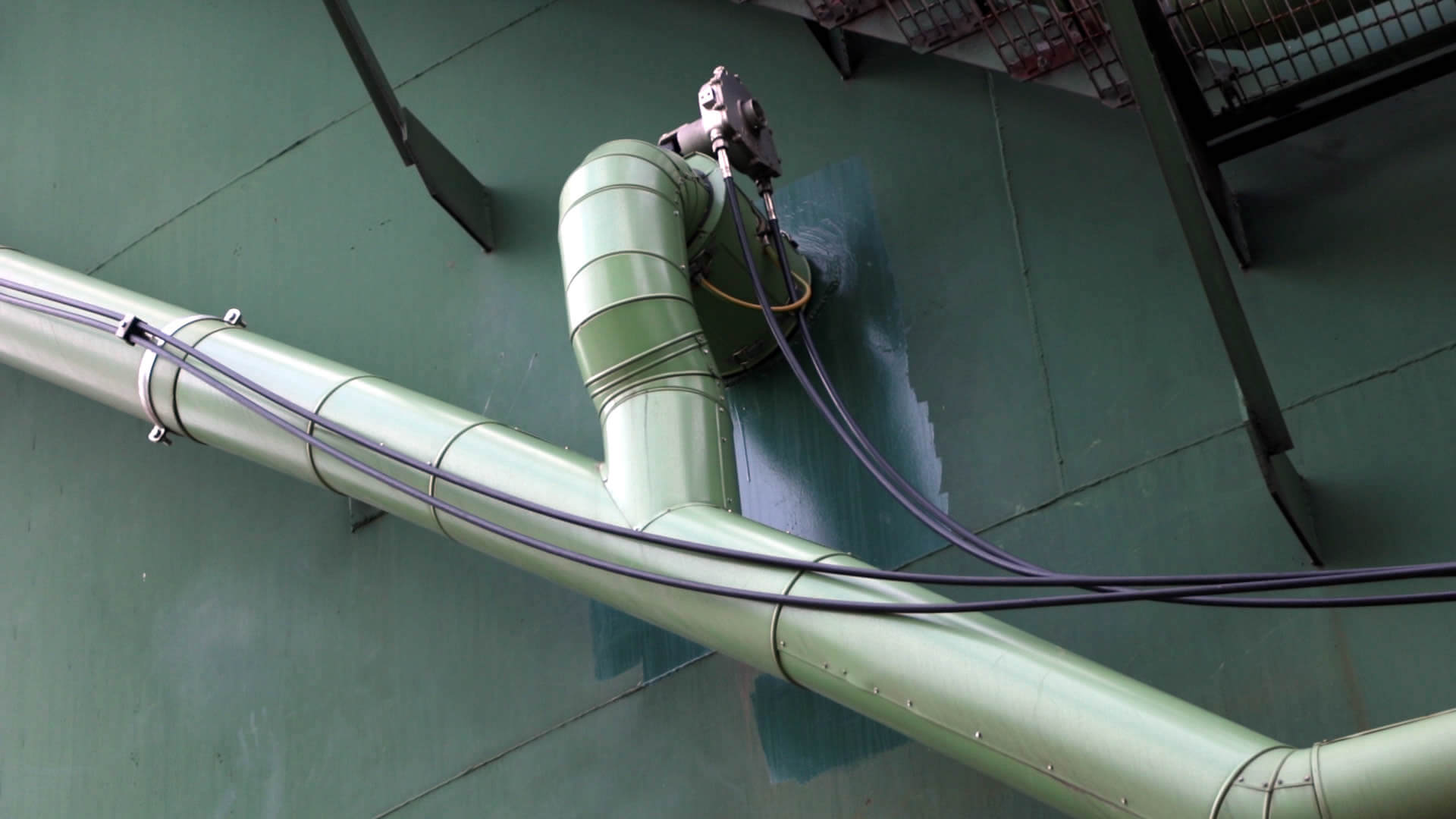

Improved valve accessibility

Even with non-critical valves, permanent accessibility is desirable. Operators may be required to operate hard-to-reach valves or faced with restricted access conditions, due to other process equipment and pipes which can in turn make the valve hard to operate. To overcome these issues, such valves can be operated using a remote valve operator. This is a cost-effective tool for companies to remotely control valve operations from a distance.

Eliminating potentially difficult design issues in a cost-effective way

The Sofis FlexiDrive allows locating a point of operation at a preferred position. This could be a safe area, or a better, ergonomic position, discouraging potentially unsafe behaviour like climbing on valves to gain access. FlexiDrive removes problems associated with confined entry points. Its linear drive cable delivers rotary torque at distances up to 30+ metres and can pass through walls and doors. Many operating companies have used this remote operator to overcome issues of accessibility. Remote valve operators fulfil Human factor Engineering guidelines, by eliminating potentially difficult design issues in a cost-effective way. It overcomes obstructions to access and can increase operator safety from valves in potentially hazardous areas.

A cost-effective, complimentary solution to the Human Factors Engineering discipline

Sofis portable actuators and remote actuators are both examples of cost-effective

solutions, complimentary to the HFE discipline. They alleviate possible safety concerns and can be used across an array of industries to support safe, and efficient valve operations.