Captive key systems enforce and guarantee a predetermined valve operating sequence to eliminate human error.

Captive key systems

Captive keys guide your operators through manual valve operation sequences, without shortcuts. Valves are operated using a linear key, taking your operators through a specific process, following a predefined sequence, with unique keys for each step. Sofis captive key systems are used as an industry standard by renowned companies like Total, BP, ADCO and Shell to create a safer working environment.

Ensure correct manual valve operations

Although some processes are automated, there are certain applications that require an element of manual operation. This raises the risk of human error, leading to incorrect valve operations, with catastrophic consequences. You should maximise safety and process uptime across your plant. By selecting Sofis captive key systems, you ensure right first time operations across a broad range of applications, simply by determining the conditions in which valves are operated.

Basics of captive key systems

Accidents in the process industry are mostly related to procedures that do not occur frequently and at the same time can have catastrophic results when performed incorrectly. 75% of the accidents in the process industry happen during startups, shutdowns and maintenance. In 50% of these accidents, root cause is incorrect operation of manual isolation valves. This is why captive keys are mostly used on pressure relief valves (PSV), but there are many other applications where captive keys (or valve interlocks) are an added value by protecting people, the environment or company assets.

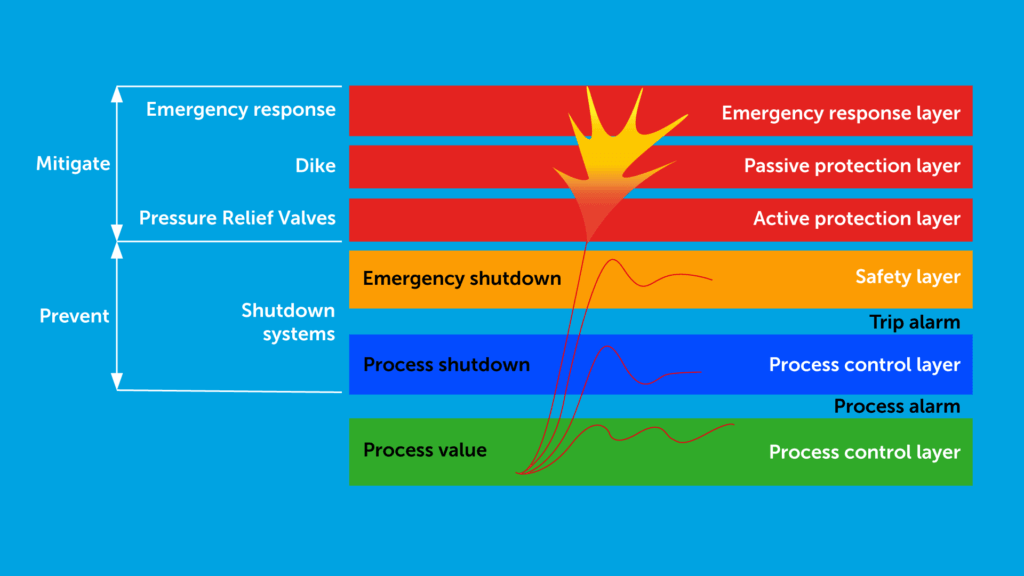

Captive key systems represent an independent layer of protection

Process facilities in the United States are required by OSHA to run a Process Hazard Analysis (PHA) every five years. The most common tool used to conduct the process hazard analysis is a HAZOP. Process safety professionals have reported a trend for PHA’s to go one step further than a HAZOP, in a quantitative study of risk termed and many scenarios are pushed to a Layer of Protection Analysis, or LOPA. A LOPA study quantitively analyses the risk of an event occurring. Commonly, companies reference quantitative values for risk set out in the Initiating Events and Independent Protection Layer in Layer of Protection Analysis manual created by the Center for Chemical Process Safety. Most organizations have adopted this book as the standard for defining and quantifying risks in initiating events and will use this book for defining layers of protection.

Simplify manual valve operations

LOPA’s often leave teams with difficult task of trying to solve complex problems, without creating complex and expensive solutions. One very common example of this is trying to simplify a manual process without the complexity of full automating the process.

Applications where teams need to control the sequence of an operating valves in a manual process include that are identified in a LOPA are:

Control manual valve operations

The most effective and simplistic solution for these complex scenarios lies on page 227 of the Initiating Events and Independent Protection Layers book, under the heading Captive Key. Captive keys employ the use of locks that prevent the movement of valves and unique keys that will only be released in the desired valve sequence, preventing humans from operating valves in the incorrect sequence.

Achieve risk reduction by implementing captive keys

The CCPS Guidelines subcommittee recommends that a Probability of Failure on Demand factor of .01 be awarded for captive keys being used to controlling sequences. This means that systems that implement captive key can be awarded two credits or decrease the probability of an accident by a factor of 100. Captive key systems are a commonly thought of as a simple solution because they are retrofitted to the current system and require no adjustments for valves or equipment.

Download our whitepaper

Find out more on achieving risk reduction by implementing captive key systems!