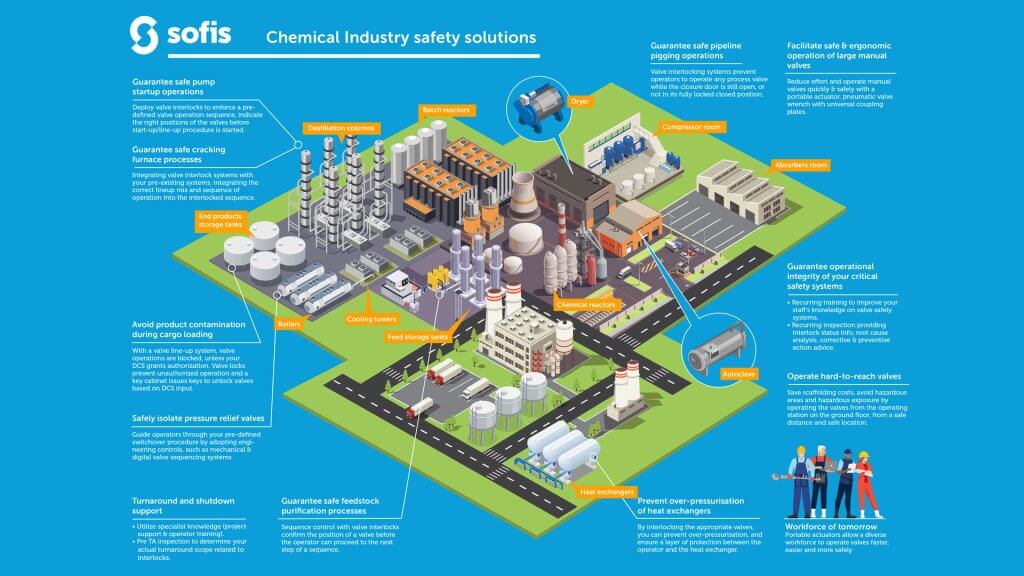

Chemical plants manufacture or process chemicals using specialized equipment, units, and technology in the manufacturing process. Chemical and petrochemical plants can pose a range of challenges and risks.

Chemical processing involves various activities such as manufacturing, handling, and storing chemicals. The various processes come with certain risks. In your facility, you can experience process failures, which can result in contamination, loss of containment, a runaway reaction, unplanned downtime, loss of production, and potentially hazardous situations leading to accidents and injuries. And as a ‘high-risk’ enterprise, you must also comply with strict safety rules.

Ensuring safe, efficient, and sustainable valve operations

Ensuring safe, efficient, and sustainable valve operation across your facility is key to protecting people, assets, the environment, and profit. Sofis products and solutions are used in many applications in the chemical industry, to guarantee safe valve operations and improve efficiency.

Safely isolating pressure relief valves

Pressure relief valves require regular maintenance and calibration. Spare relief valves maintain sufficient relief capacity when a pressure relief valve is taken offline for maintenance. Switchover procedures require that the spare pressure relief valve is commissioned before any relief valve can be taken offline for maintenance. Often, pressure relief valves are being operated manually, meaning that valve operations are prone to human error. This can lead to extremely dangerous situations.

Guarantee safe cracking processes

Steam cracking furnace operations are generally known to be potentially dangerous and complex to manage. There have been, over the years, serious accidents and incidents involving steam cracking operations that illustrate the dangers involved. The areas where incidents or accidents have a high probability of occurring are start-up, shutdown, and hot-swapping processes. By integrating valve interlocking systems with your pre-existing systems, seamlessly, you can future-proof your plant for many years to come, extending and enhancing your operation.

Guarantee safe feed stock purification processes

Sieving and drying feedstock is necessary to avoid damage to your chemical manufacturing equipment. The process of regeneration is extremely dangerous, and a correct line-up of valves must be achieved before starting the regeneration process. Unfortunately, there are many accidents tied to this procedure.

Offering you over 38 years of experience

With over 38 years of expertise in valve operations, we have the knowledge and expertise to fully support our customers, across industries and geographies. We have led and developed the valve interlock/captive key market over the last three decades with over 400,000 interlocks installed globally, evolving into specialists and creating smart valve solutions to secure and optimize your manual valve operations and improve process and operator safety. Our customers know they can count on us for the technology, services, and consultancy they need to ensure controlled, safe, and compliant critical valve operation processes.

Our experience

Our solutions are used by renowned companies in the chemical industry.