A long-established terminal in The Netherlands employs Sofis VPI position indicators to prevent incorrect valve line-ups. The terminal consists of 11 jetties to handle the demand. It provides deep water access and has a capacity of over 1 million m3, and serves a strong gasoil market. It has established itself in the storage and handling of biofuels and bio-feedstocks.

Correct valve line-ups from the jetty to the tank

In its strive to avoid contamination, and guarantee safe valve operations, terminal management recently decided to evaluate amongst a variety of solutions that could help them prevent contamination during loading and offloading operations. The solution had to be retrofitted to existing gate valves. When loading, a number of valves need to be lined up from the jetty to the correct tank, and in case of offloading, from the tank to the jetty. Typically, this is a manual process, requiring the operator to open specific valves, which need to be opened for that specific route. If incorrect valves are opened, the product will be transferred to the wrong tank, causing contamination. Incorrect loading and offloading procedures must therefore be avoided at all times, as they can result in high direct costs as well as damage to the terminal’s reputation.

Valve actuation

When looking for ways to improve the safety of their loading operations, the terminal had to choose from a range of solutions. Valve actuation was considered a logical option. However, if manual processes are still relied on, this option requires heavy investments. This is why management decided to evaluate other solutions, that would allow to make substantial improvements without the need for full automation.

Real-time valve monitoring

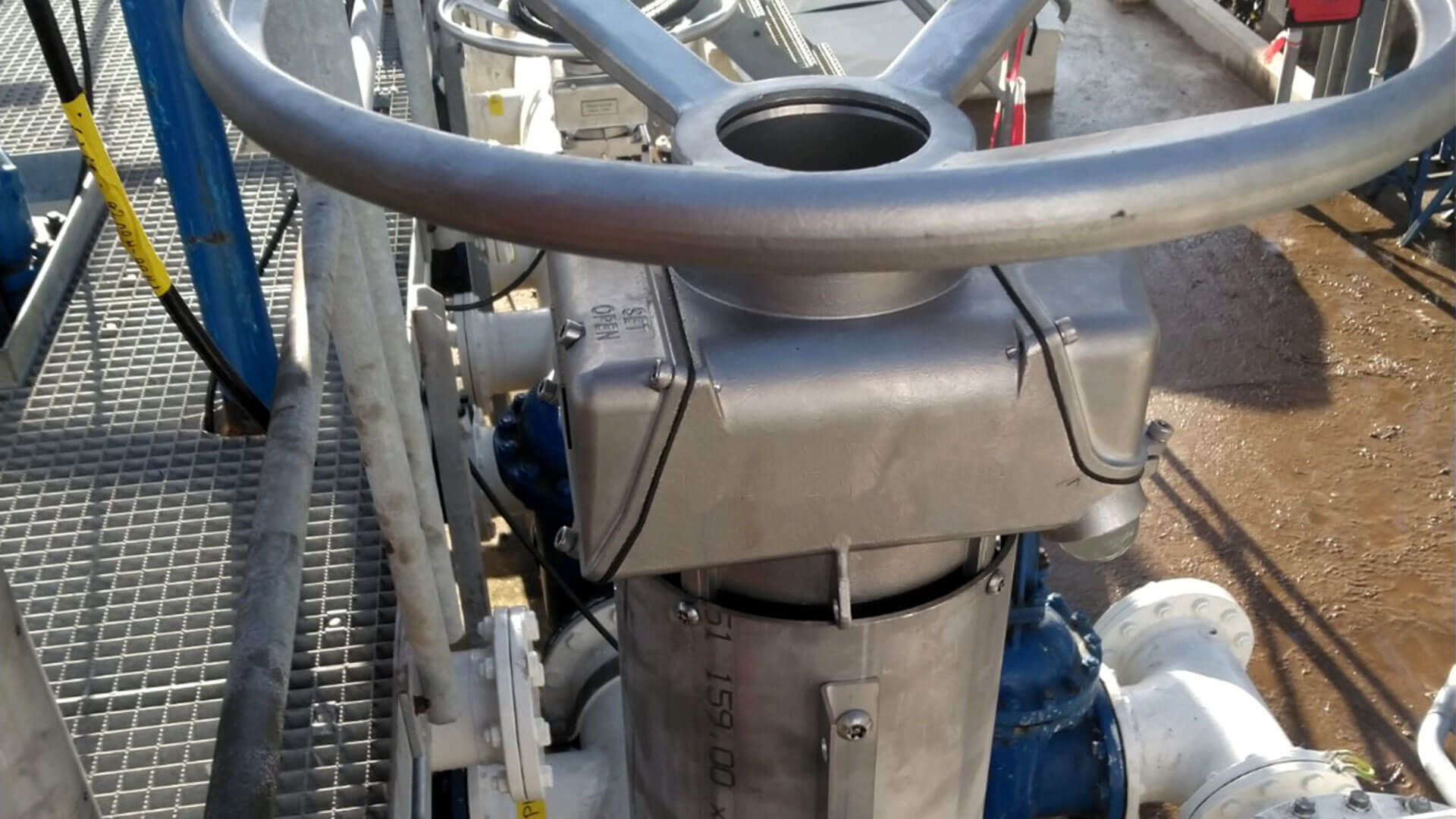

To ensure correct valve operation, without the need for heavy investments, this terminal chose to install Sofis VPI position indicators onto its valves. VPI detects errors timely, with real-time monitoring, allowing terminal management to continuously monitor valve line-ups, without limiting the operators’ autonomy. The solution ensures all valves are in the right position, to eliminate errors that lead to contamination incidents. VPI position indicators have been mounted to the existing manual gate valves, to monitor the terminal’s valve positions in real-time.

Adaptation of VPI mounting kit

To connect the VPI position indicator to the valve, Sofis had to produce a custom-made solution for gate valves with rising spindles, even up to 1.2 meters. For this purpose, Sofis design engineers engineered a custom spindle extension, to replace the existing extension. This extension allows the VPI position indicator to be fitted to the valve correctly, without having to mount it to the railing of the existing valves.

Secured valve line-ups

The VPI position indicator provides up-to-date status information and allows terminal management to monitor and control manual valve operations. By using our VPI position indicators on manual valves, the terminal management receives the valve position signals in their DCS. This way, they can ensure loading and offloading are only started when the correct line-up is completed.