Valve interlock systems eliminate human error and guide valve operators through predefined valve operating sequences.

Valve interlock systems prevent accidents

Valve interlock systems force valves to be opened and closed in the correct order

Most accidents in the process, and oil and gas, industries are related to procedures that do not happen very often but which can have catastrophic effects when performed incorrectly. Start-ups, shutdowns and handovers are all good examples of processes where a slight mistake or lack of concentration can lead to disastrous consequences. By using valve interlocks, you force operators to follow the correct valve opening and closing procedure and so create safer working environments. Valve interlocks also reduce costs by preventing product spills or losses due to incorrect changeovers.

Key transfer

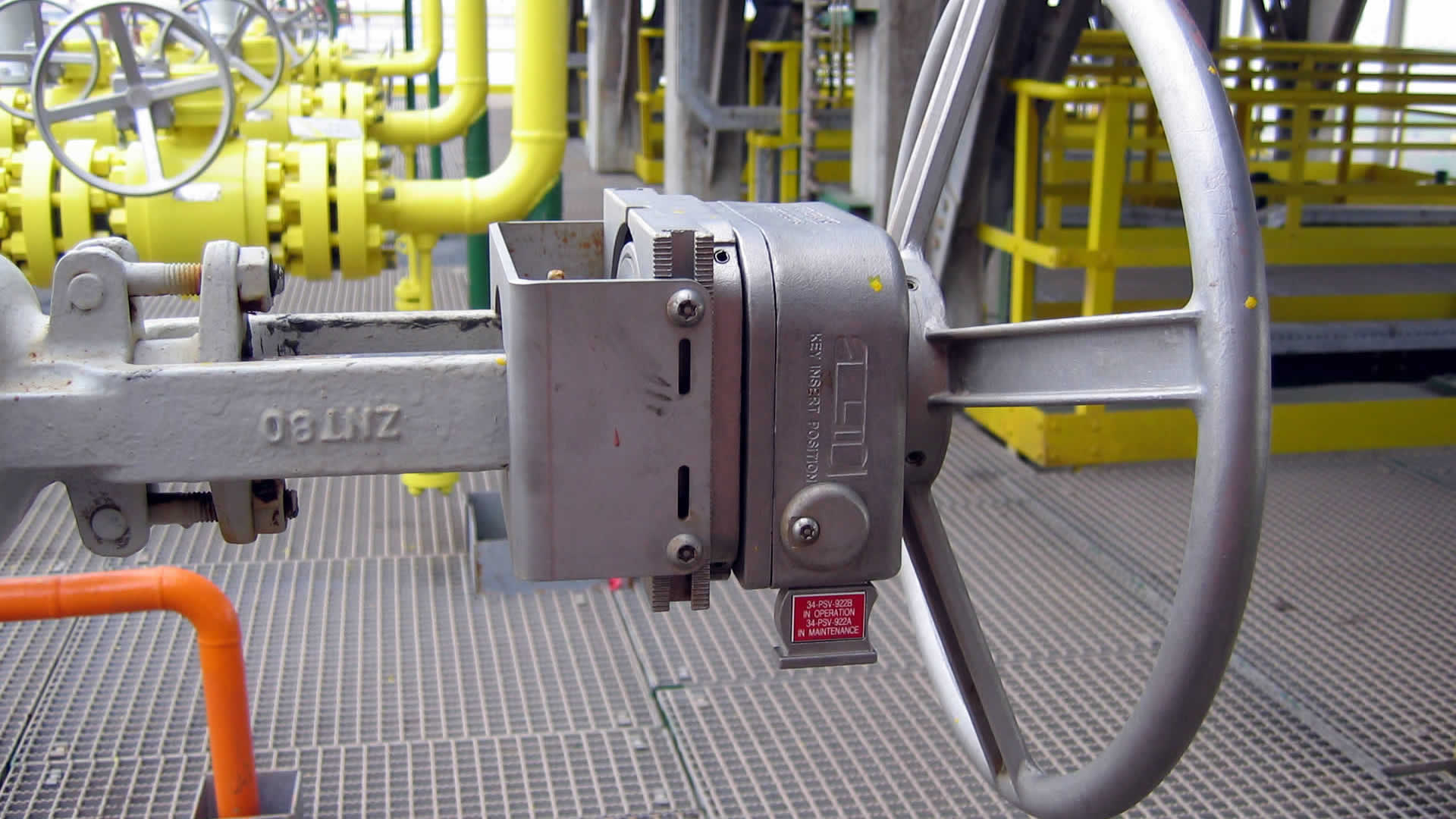

A valve interlock system guides the operator through a predefined sequence with unique keys for each step. Each valve interlock is supplied with two keys, one for the locked-open position and one for the locked-closed position. When the valve is open, the ‘open’ key can be released and transferred to another lock with the same code. All keys are unique and, depending on the sequence, Sofis will determine the codes to guarantee the required sequence.

Applications

Smith interlocks and Netherlocks interlocks from Sofis are used for a wide variety of applications, such as pressure relief valves (PSVs), pig launching and receiving, decoking, inert gas systems, pump start-up, flare lines, boiler blowdown, 2 out of 3, chemical dosing pots, HP fuel gas heaters, closed drain drums, vessel filling, vessel isolation, gas train alignment and pump routing.

How does a valve interlock work?

Valve interlocks are used in many applications where valves need to be operated safely and correctly the first time. This video explains the basic functionality of the valve interlock.

Installing a valve interlock

Valve interlocks can be mounted without any alteration to the host valve; the characteristics of the valve remain unchanged. The valve interlock is installed as an integral part of the valve, with the original valve lever or hand wheel removed and replaced with a new sliding lever or hand wheel.

How can we help you?

Do you need help setting up safe valve operating procedures with valve interlocks? Our global team of engineers is available to assist with interlock sequence design. They are committed to improving your valve operations and, ultimately, your plant performance.